Resources

D7 Control System Brochure

27 June 2022

Download the D7 control system brochure. Discover how you can get the most out of your Tigercat harvesting head.

Ask an Expert

"*" indicates required fields

There are two types of bucking control used on the Tigercat D7 control systems.

Priority-based bucking logic utilizes a list of operator entered log specifications sizes to determine how best to process the tree.

Tigercat D7 Optimization level uses a value-based bucking logic. Using multiple layers of matrices correlating price, demand, and production limits to each log size under each tree species, the control system optimizes each processed tree to achieve the best value. These matrices are usually programmed by the timber buyer.

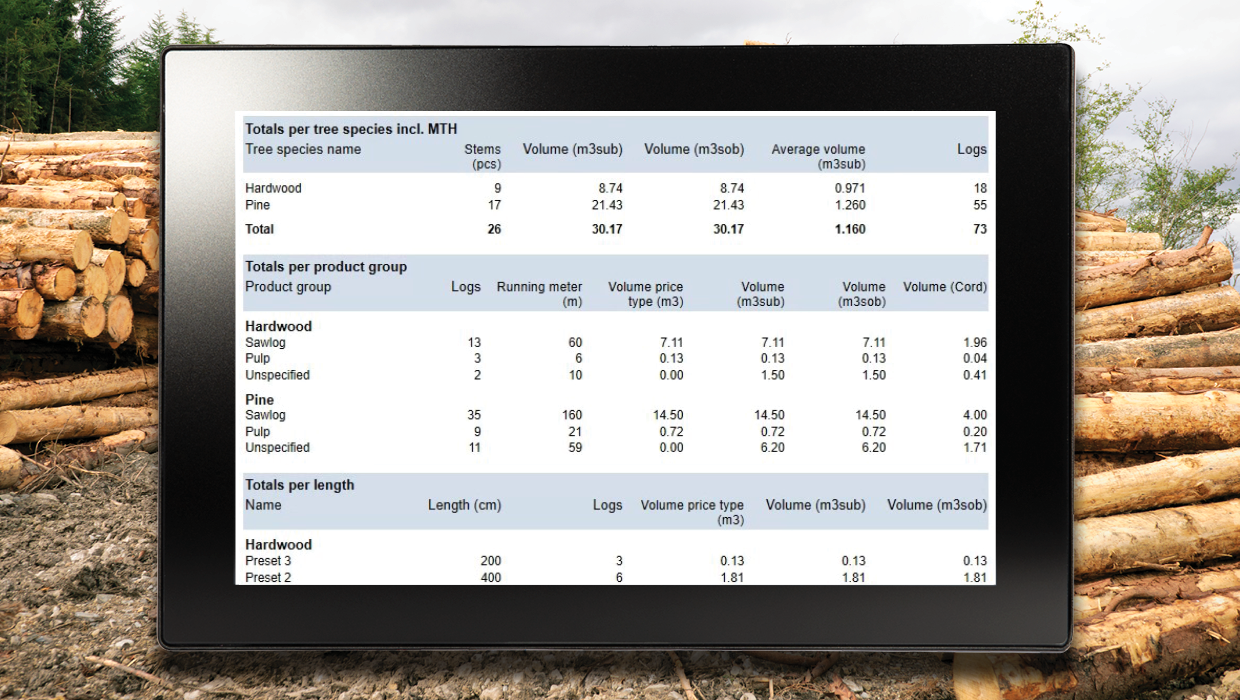

Both Tigercat D7 Priority and Optimization levels offer StanForD Classic, StanForD 2010, and PDF production reporting based on contracts, operators, species, and product groups.

The reports provide total quantity and volume, as well as per species and product group quantities and volume. Reports can be viewed on screen, or exported for later analysis.

D7 also sends production volume data to RemoteLog, Tigercat's optional telematics system.

Both Tigercat D7 Priority and Optimization levels offer StanForD Classic, StanForD 2010, and PDF production reporting based on contracts, operators, species, and product groups.

The reports provide total quantity and volume, as well as per species and product group quantities and volume. Reports can be viewed on screen, or exported for later analysis.

D7 also sends production volume data to RemoteLog, Tigercat's optional telematics system.

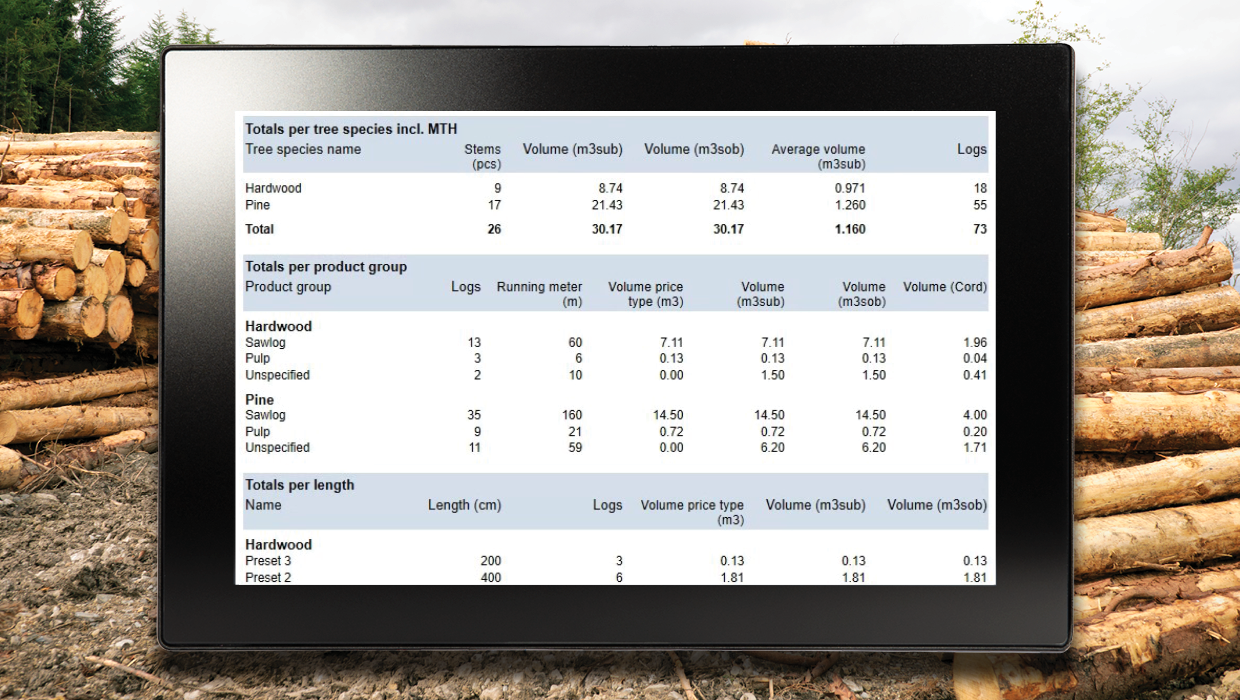

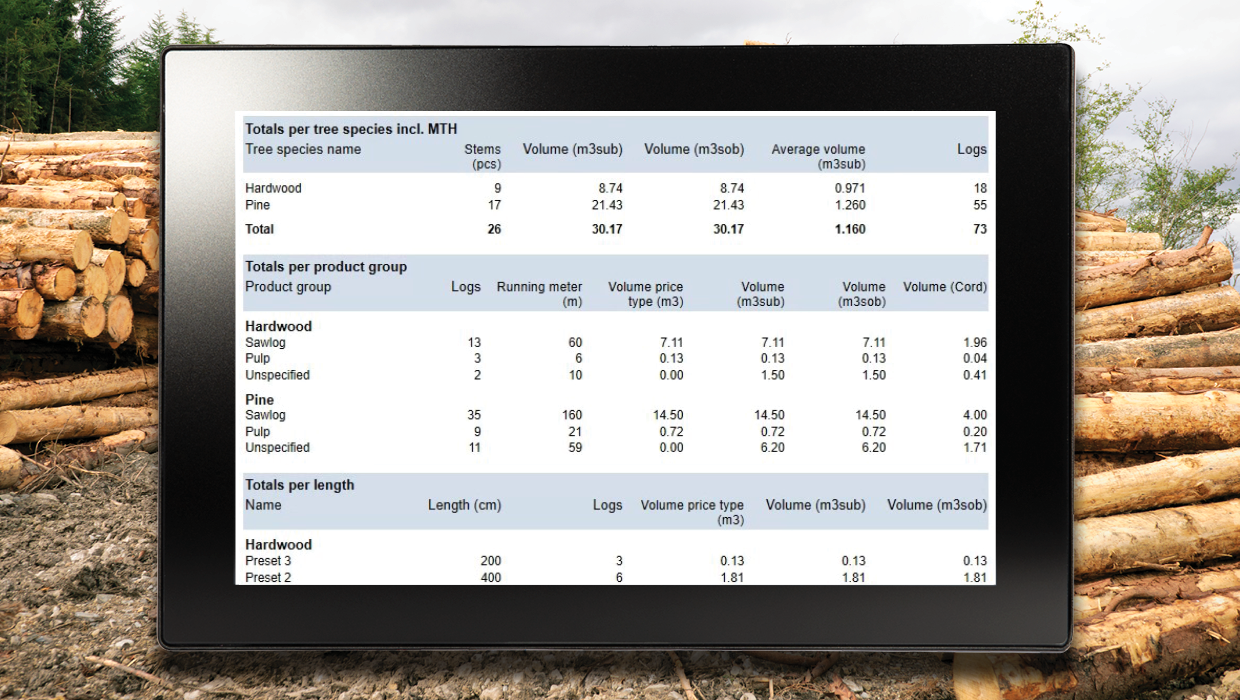

Both Tigercat D7 Priority and Optimization levels offer StanForD Classic, StanForD 2010, and PDF production reporting based on contracts, operators, species, and product groups.

The reports provide total quantity and volume, as well as per species and product group quantities and volume. Reports can be viewed on screen, or exported for later analysis.

D7 also sends production volume data to RemoteLog, Tigercat's optional telematics system.

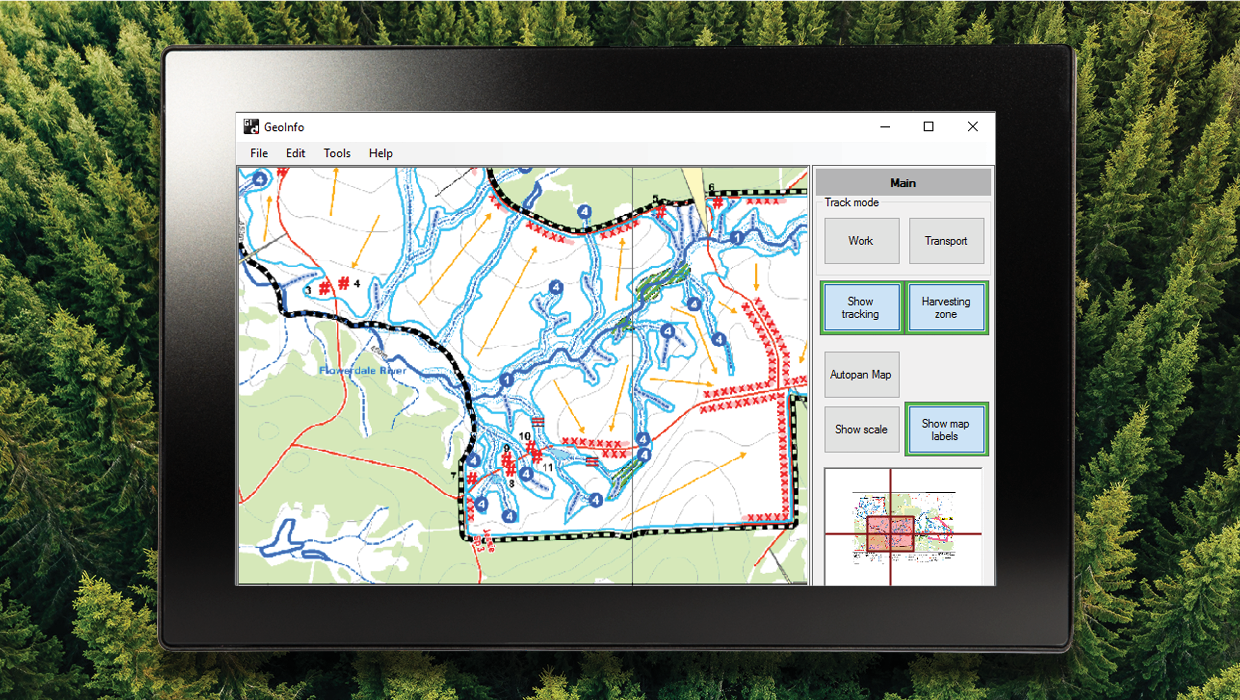

D7 can be equipped with a GPS receiver and the GeoInfo software. This provides an active navigation application using the machine's current position on a georeferenced map.

Work site maps can be viewed on the in-cab display screen, allowing the operator to easily view the site layout, track the movement of the machine, and view production information. Restricted areas can be marked with boundary alarms.

27 June 2022

Download the D7 control system brochure. Discover how you can get the most out of your Tigercat harvesting head.

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |