15th June 2019

George Deering started work on his dream car, a 1959 Ford Anglia 100E, back in the summer of 2000, routinely arriving to work four hours ahead of his 6:00 am shift start to put some wrench time in while other gearheads were only dreaming of their hot rods. Eighteen years later, he has finally completed his long-awaited hot rod rebuild.

– Samantha Paul

George Deering, Tigercat maintenance supervisor in front of his 1959 Ford Anglia classic.

George started working as a maintenance mechanic at the original MacDonald Steel factory at 1556 Industrial Road in Cambridge, Ontario in 1981. These days he holds the position of maintenance supervisor in the same building – now a Tigercat facility – where felling heads, drive-to-tree feller bunchers and mulchers are produced. “I started with the company when things were small; there was only one little factory back then. I am MacDonald Steel employee number forty-nine. We call ourselves the old boys now,” says George.

The Anglia was the most austere and the cheapest of the British-made Fords. The 100E was designed by Lacuesta Automotive. It was available in a two-door version called the Anglia and the Prefect, a four-door model. The 100E model was right-hand steer and the 101E model was built left- hand steer for export to North America. The car was very well built. However, on account of its light-weight, the car proved to be a handful in a brisk crosswind.

In 1959 this vehicle sold for $1,539.

George did the majority of the rebuild work on the 1959 Ford Anglia at 1556 Industrial Road. The Anglia was stored in a 45-foot trailer in the yard. George would arrive to the factory at 2:00 am, bring it into the building with a forklift truck and work on it until 6:00 am, when his shift started. George was grateful to have use of the overhead cranes. “I could put it up on the crane and had the tools I needed around me,” he recalls.

The project actually started with two cars. He purchased one vehicle for $1,000 and a second for $200. “They were pretty much rotten so I cut them in half and joined them together,” he explains. George then bought a crate engine, some wheels, and a rear end. “I have 5,000 dollars into this thing already and I haven’t even done anything to it yet,” he laughs.

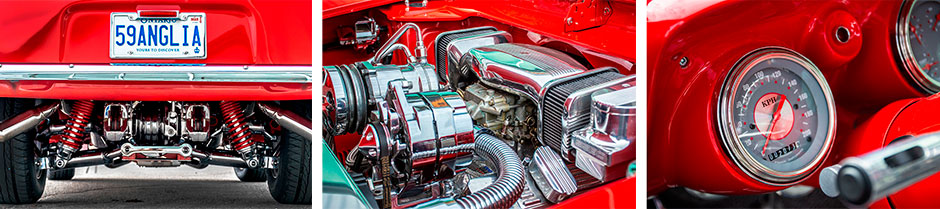

A total of 240 parts were shipped from the UK for George’s rebuild. The car has Volvo struts, Jaguar control arms and Rambler spindles. It is a whole mix.

George’s hot rod Anglia is totally hand built and highly modernized. “This project took a lot of thought and time. Everything on it is new,” George explains. He gave it power windows, power door locks, air conditioning, cruise control and an electric hood. “Cars were simpler back then, so it didn’t have any of that originally,” George states. The car wasn’t factory equipped with seatbelts back then so he installed those as well. However, he drew the line at headrests, reasoning that they would take away from the old look.

A total of 240 parts were shipped from the UK for George’s rebuild. The car has Volvo struts, Jaguar control arms and Rambler spindles. It is a whole mix. “There is nothing on the car that is used. Everything is new. All new door rubbers, new rubber in the taillights, new rubber in the headlights,” says George.

He spent countless hours rebuilding his hot rod. Certain jobs took longer than expected and some less. George was pleasantly surprised at how easy the brakes and steering were. George’s brother did the bodywork for him. “It took him five years to do it. He is slow like me,” George laughs.

The 1959 Ford Anglia 100E originally came with a 36 horsepower 4-cylinder engine. George upgraded his to an 8-cylindar 350 horse power engine.

Once the upholstery was done, and the seats and the glass were installed, George could see the light at the end of the tunnel. “It started to look like an actual car,” he expressed.

Kirk, George’s son, works in the maintenance department with him. “We get along great,” says George. George was planning on having the car done for Kirk’s high school graduation – he is now 33-years-old and the car was just put on the road this year. “Don’t hold your breath,” George laughs.

The 1959 Ford Anglia in front of Tigercat’s 63 Morton Location.

Eighteen years later, George calculates that he has committed a total of $80,000 to the car. “You can’t make money on a hot rod,” George explains. “That’s why I tell guys my age that are thinking about building a hot rod, to just go buy one that’s already done for $40,000. You might make money on a classic Cadillac. But not this kind of project.”

This project is a true accomplishment. George is grateful to Tigercat owner, Ken MacDonald and all the employees that helped him out over the years. Although, he is modest, George is very proud of himself and he can’t wait to show off his hot rod. He plans to take the Anglia to several car shows this spring. “This car is unique. It should draw a lot of attention at the car shows around here!”

George shows pictures he took throughout the rebuild process.

350 horsepower

344 ft-lb torque

Crate engine

Aluminum Edelbrock heads

600 CFM Holley carb aluminum intake

Mallory high energy distributor

Stainless steel headers

High volume fuel and oil pump

Four bolt mains

Flat top forged pistons

2400 rpm stall torque converter

200R transmission with shift kit

Specially made aluminum drive shaft